Dealing with Cavitation Wear in Hydraulic Systems

April 29, 2015

One issue that can be highly problematic when it comes to hydraulic shears is cavitation wear. As a general rule, the occurrence of cavitation can be minimized in a number of ways. The first step that should be taken to reduce the risk of cavitation wear is to purchase a hydraulic guillotine shear that is built by a quality manufacturer, such as Preci-Shear. Preci-Shear has developed a reputation for building high-quality, custom hydraulic cutters — meaning that the materials used to make the hydraulic guillotine shearing machine is extremely durable. This durability means that it is less likely that cavitation will occur.

Proper Maintenance

Another important step in protecting hydraulic equipment from cavitation wear is consistent and proper maintenance. When the fluid is changed regularly and all worn parts are replaced, the chance of creating a cavity is less likely.

Design is Also Important

It is not only the quality materials that Preci-Shear uses that allows them to consistently produce the top hydraulic shearing machines, it is also their impressive and innovative designs. This company designs hydraulic cutters that not only last, but they also perform at an exceptional level. The ability to combine exceptional design with quality material is why Preci-Shear is considered to be one of the top hydraulic shearing machine manufacturers in the world.

Identifying the Key Signs of Cavitation

There are three primary signs that are indicative of cavitation wear, abnormal noise, high temperature and slow or substandard performance. It is important to detect and respond to either of these signs expeditiously, because the longer that you procrastinate in addressing these issues, the worse that the cavity will get and the more damage will be done to the machine.

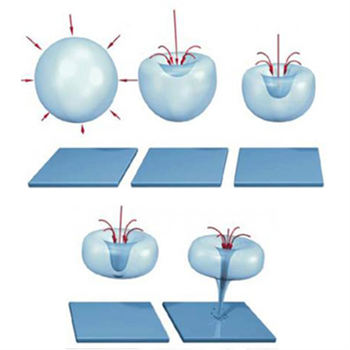

There are two primary causes for abnormal noise. The most alarming noise is normally the result of what is known as aeration, which is a situation in which large air bubbles get trapped in the system and as they are compressed and decompressed, they make a loud, hammering noise. If not properly engage, this can lead to equipment failure.

When the noise is due to cavitation, it is the result of the pressure falling below the vapor pressure of the fluid, producing what is known as vapor cavities. Eventually, these cavities will implode, and when they do, they will produce a loud knocking sound. If you suspect cavitation, you can have a service technician come out to inspect the equipment. They will be able to identify the cavitation issue by using vibration sensors or acoustical analysis equipment.

You should also pay attention to the fluid temperature. If the temperature is higher than normal, the system should be examined to determine the cause. The same applies to poor machine performance.

As with any problem associated with your hydraulic cutter, the moment that a problem is detected, it is advisable to address the issue immediately, because the longer that the problem goes untreated, the more damage the machine will incur.