Avoid Shear Frustration: 8 Tips For Maintenance

August 29, 2014

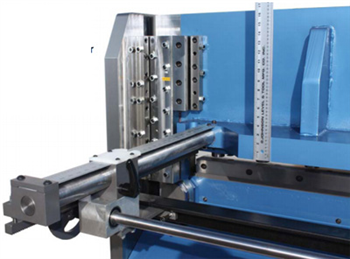

Metal cutting is high tech, well beyond the age of the saw. Shears are found in diverse industrial settings including tube mills, large machine shops and small scale fabricators. The hydraulic cutter, also called a squaring shear or hydraulic guillotine shearing machine, is considered the workhorse of the metal processing industry. It is known for the quality and precision of the cutting, high capacity and high output.

These machines are built from heavy duty materials but utilize advanced design and technology. To maintain their high productivity and increase their useful lifespan, they need regular maintenance. Here are eight tips to keep your hydraulic guillotine shearing machine in top condition.

#1. Know the limits and specifications of your machine.

According to makers of these tools, trying to cut metal beyond the manufacturer’s specified limits is the most common reason users need to call in a repair person. Overloading it for short-term convenience can cause major long-term damage.

#2. Inspect it regularly.

Make the recommended adjustments on a regular basis, including lubricating and caring for the blade. The inspection routine should include checking for wear and tear, for lost motion, and that safety and emergency devices are in good working order.

#3. Monitor data gathered from routine inspections.

Analyzing inspection reports provides early warning of patterns of wear and the chance of accidents. Consistent monitoring is the foundation of preventive maintenance. Scheduled inspections, maintenance and monitoring will prevent the need for most emergency repair calls.

#4. Use a preventive maintenance plan.

This needs to include four steps: make sure the air system is clean, lubricate according to manufacturer’s guidelines, check the clutch and brakes for signs of wear and tear, and test the counterbalance cylinders for leaks and indicators of failure.

#5. Adjust the blade correctly.

The blade is the workhorse of a hydraulic guillotine shearing machine. Spending time to set it properly will extend its life and limit downtime. The correct blade clearances affect a range of functions, including the quality of the cut, the drive and ram, as well as the tooling. To avoid blade shifting, which causes chipping, be sure to check regularly for flatness. Hydraulic shearing machine manufacturers like Preci-Shear provide the correct seating specifications that need to be followed.

#6. Monitor and adjust gib clearances as needed.

Your hydraulic cutter will last longer if you set and maintain the gib clearances according to manufacturer’s guidelines. Its purpose is to guide the ram and the attached tooling properly. When the clearance it incorrect, the result is damage and reduced useful tool life.

#7. Level the machine, isolate it from vibration.

In order to properly function, the machine needs to be completely level and removed from the effects of vibration. Isolation pads can help increase its lifespan by lessening the vibration. They also reduce noise levels and avoid the problem of shear frame distortion.

#8. Make needed repairs as soon as damage is found.

Adjust or repair the shear as soon as you find a problem. This extends its useful life and keeps it safe for the operators. Doing the work quickly is less expensive than calling in a repair person or even replacing the equipment.