The Benefits of a High Quality Precision Guillotine Shearing Machine

October 30, 2014

Preci-Shear has developed a stellar reputation for incorporating quality and precision into the design of their guillotine shearing machine. These hydraulic shearing machines have the capacity to meet the specific needs of their customers.

Design the Preci-Shear way

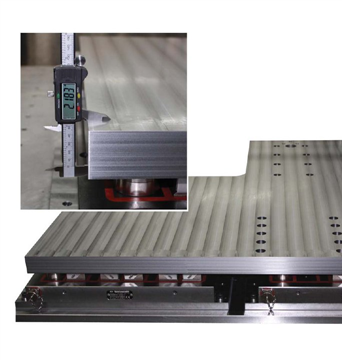

Where most precision guillotine shear manufacturers have chosen to go with more lightweight designs as time has progressed, causing issues with deflection, meaning there was a need to make rake-angle and blade gap adjustments, Preci-Shear has chosen to stay with a massive frame structure that has the capacity to reduce the level of deflection, allowing the operator to be more precise with their cutting.

The strength and weight that the massive frames produce makes it easy to handle the materials being cut. This is because the machine will outweigh the material.

Some of the primary benefits of a Preci-Shear precision shearing machine are:

- Standard replacement parts, meaning that parts will be easy to locate, and the cost of the replacement parts will be minimal

- The design extremely simple, facilitating the ability to make precise cuts

- Has the capacity to cut varying sizes without the need to make adjustments to the machine

- The rake-angle and blade-gap are fixed — this if supported by the massive size and weight of the machine frame

- There is no threat of the cutting materials folding

- Blades are standard D2 high carbon steel

Guillotine Shear Replacement Parts

Because the precision guillotine shear is made with standard parts that are easy to find, it reduces the maintenance, repair and part replacement cost. All of the parts used on the machine are common and can be easily found. This means that the cost mechanisms involved are extremely low, making the maintenance of the machine simple and inexpensive. When there is a need for repair, which is rare, the repair can be done cheaply and quickly.

Precise Each and Every Time

Preci-Shear is one of the leading hydraulic shearing machine manufacturers in world. There are a number of reasons why they have been so successful. One of the most important reasons guillotine shears produced by this company are so precise and dependable, is that the company has learned not to tamper with perfection. While other companies are following the trend of building lighter machines, the designers at Preci-Shear understand that it is the weight of the machine that provides the stability necessary to handle heavy materials without the need of adjustments, which has the capacity to negatively impact the accuracy and precision of the cuts.

When you have a high quality precision guillotine shear, you will be able to achieve a good parallelism and linearity of the cutting surface — all while avoiding warping — leaving the operator with a perfectly cut piece.