The Importance of Precision and Quality with Hydraulic Cutting Shears

February 25, 2015

There is no questioning the fact that the demand for highly specified hydraulic presses and hydraulic cutting shears has increased exponentially over the past several years. Metal working companies are consistently being bombarded with demands for highly specified results. This means that the machines that they used must have the capacity to achieve a high level of specificity while producing consistent results. An immensely important part of ensuring the quality of your next hydraulic guillotine shearing machine is to make sure that you are purchasing it from one of a hand full of quality shearing machine manufacturers such as Preci-Shear.

Preci-Shear stands on the guiding values of quality, precision and performance, and they use these guiding values as the foundation of every design. They understand that quality, precision and performance substantially increase the efficiency at which a project is executed. Although innovative design has its benefits, Preci-Shear understands the importance of building on a traditional foundation that has a proven track record of performance, subsequently they build guillotine shears that have the capacity to outperform the average hydraulic press shearing machines.

Precision is The Product of Detail Orientation

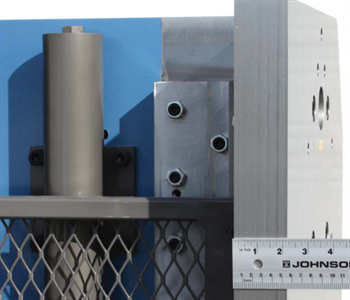

The precision of any hydraulic cutting machine is associated with the level of detail that was given to the design and the materials used. For instance, the proper consistency and the width of the blade gap is extremely important to achieving the optimal level of quality when cutting metal. At the end of the shear stroke and the point of the cut, the cutting blades are actually separated by centimeters, providing the ideal space for the removal of metal fragments that are broken off during the shearing process.

This is where precision and detail come in. If this gap between the blades is too narrow, it will create a backup of those metal pieces, as they will not have a place to go. This backup will inevitably create added pressure on the blades, introducing a number of issues, which may include an inhibited cutting capacity. This minimizes the efficiency of the machine, and it extends the length of each job. A gap that is too wide can also create performance problems. This is why it is paramount that a substantial amount of detail be given to every aspect of the design of any hydraulic guillotine shearing machine.

You Cannot Beat Old Fashion Ingenuity

One of the problems with a great deal of contemporary shearing machines currently on the market is that they are manufactured using light weight material, but unfortunately, this has a tendency to impact the level of stability when cutting. It is actually the weight of the machine that provides the stability. This is why quality manufacturers such as Preci-Shear continue to use high quality, weighted materials in their designs.

If your company is looking for machines that are highly efficient and get the job right every time, it all begins with choosing the right manufacturer. Always go with a name you can trust.