Guidelines for the Safe Operation of a Hydraulic Guillotine Shearing Machine

May 07, 2014

Considered to be an important piece of equipment that has the capability and power to save time and an operator’s energy, a hydraulic guillotine shearing machine also has the ability to cause serious injuries. However, following certain safety tips significantly decreases the potential for injury. Let’s look at common safety practices that should be followed at all times when operating a hydraulic guillotine shearing machine.

Before You Start

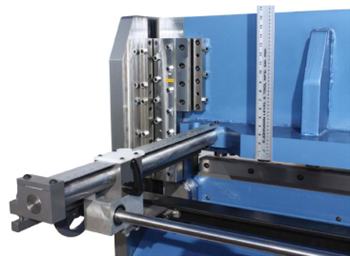

It is important to know the equipment before you ever begin to use it. It is a good idea to start by familiarizing yourself with the hydraulic safety shearing machine manufacturer manual. Any time you start to operate the machine, complete a thorough check of the parts beforehand. Ensure that the brake is in working order, no rusting is evident, parts are well lubricated, blades are sharp, and all screws are tight and unable to loosen. Make certain that fixed guards are in place to prevent any part of your body from getting caught in the trapping space. If there is any question as to whether the machine is in good working order or the fixed guards are properly positioned, alert a supervisor for further instructions.

Also, survey your work area checking for sufficient lighting, free of any tools or scraps that could cause you to trip, and be aware of any employees that may be working in close proximity to the machine. Set up a perimeter to prevent others from entering your workspace.

While You Are Cutting

Modify the barrel distance to one that is in accordance with plate thickness. Never attempt to exceed the rated capacity. Lift large sheets of material based on your employer’s lifting guidelines to decrease risk of hurting your back. Check the placement of your hands and fingers before you begin to feed the material through the blades. When doing this, you should hold the material firmly to prevent it from slipping

Monitor carefully for the buildup of short ends, slivers, or any other debris. If trash accumulates, stop and remove it from the area around the blade.

In The Event The Machine Stops Working

If the machine begins to make a strange sound, immediately break the switch and cut off all power to the machine. If the machine cuts itself off, also cut off the power source to the machine to ensure your safety before you begin to examine the machine. You must identify the source of the problem and ensure that it is properly corrected prior to restarting your project. It’s a good idea to use the hydraulic safety shearing machine manufacturer manual as a reference guide while doing this.

When You Are Finished

Make certain the power supply is cut off before removing any debris or off cuts that may be left on the machine. Dispose of them according to company policy. Finally, place the machine back in its assigned location and ensure your work area is neat and clean. This is essential to prevent an accidental injury to the next person who uses that workspace.