Factors Which Influence Cut Accuracy

July 14, 2015

Preci-shear has established itself as one of the leading manufacturers of hydraulic guillotine shears in the world. One of the reasons that this company has been so successful in achieving such a high level of recognition and respect is due to the fact that they give a substantial amount of attention to the precision and accuracy of the machines that they design and manufacture. In order to accomplish this they must first possess an exceptional knowledge of what factors actually influence the precision and cut accuracy on a hydraulic cutter.

The Design of the Shear

There are a number of elements associated with the design of a guillotine shearing machine that impact cut accuracy, and those hydraulic shearing machine manufacturers that are most successful understand that precision and accuracy begins with design. One of the most impactful elements of design that many contemporary hydraulic shear designers have missed is stability. While many newly designed machines have taken steps to lessen the weight of the machine, Preci-shear understands that the weight of a guillotine shear is a significant aspect of the stabilization process. When a machine is not stable, it is virtually impossible to guarantee precision and accuracy.

Blade Spacing is Immensely Important

There is commonly a significant amount of attention given to the material from which the blades on the guillotine shear are constructed; however, the spacing between the two blades plays a significant role in ensuring the precision and accuracy of the machine. It is obvious that when the blades have too much space between them, it can negatively impact their precision and the ease at which they cut; however, what might not be as obvious is the fact that having the blades too close can also negatively impact accuracy and precision. There has to be enough space to allow for shear-debris to freely move out of the way of the cutting process.

The Quality of the Shearing Blades

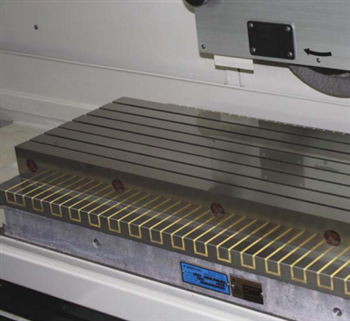

As much as the positioning of the blades plays a role in producing an accurate cut, the quality of the blade also plays a major role in the process of producing consistent and accurate cuts each and every time. With Preci-shear, the blades of their hydraulic shears come standardly equipped with sectional blades that are created with high grade D2 high carbon steel.

The company invested in a number of rigorous tests that revealed that the use of sectional blades not only made the machine more user friendly, but it also served to provide a more consistent and accurate cut. The fact that sectional blades are shorter than other blades, it makes them easier to handle and replace, when necessary. Additionally, the fact that they are short means that there will be less stress applied to each blade.

The guillotine shears that are manufactured by Preci-shear are designed with machine shops that offer highly customized products in mind. These machines are designed to produce a finished product with a remarkably high level of specificity and accuracy. Preci-Shear is recognized for the quality and durability of their machines as well.