Deciding between a hydraulic guillotine shear and a swing beam shear

June 05, 2014

Hydraulic shearing machine manufacturers are continuously improving the design and performance of their products to meet customer requirements. Preci-Shear realizes that small changes in design can mean increased ease of Two of the most popular types of shearing equipment are the hydraulic guillotine shearing machine and the swing beam shear. When determining the best type of hydraulic cutter to meet your fabrication needs, it's important to first assess your needs. equipment operation and increased productivity for clients. While both perform the same type of functions, it's helpful to understand how differences in the way that each work that may make a difference in your level of productivity for specific projects.

Determining your needs

Assess the types of materials you will be working with and the kind of shears you'll need to make. You should consider factors such as plate bend because of the density of the materials such as aluminum vs steel, paper vs plastics, and the PSI that will be needed from the machine. Additionally, will your jobs require adjusting the shear angles? Some blade angles are adjustable and others are not. This will help you choose the machine that will best serve your needs. In addition to this, bear in mind distortion factors for the materials you will be using, and figure out which shearing style will work best.

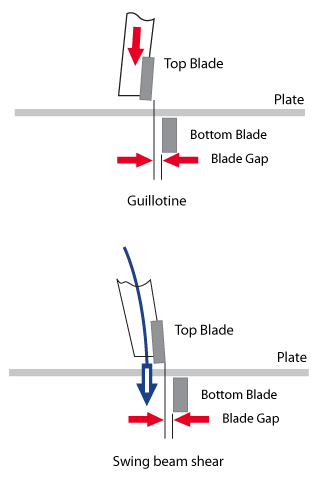

Swing beam shear

The cutting angle of the swing beam shear is fixed, so it cannot be adjusted. It also uses a semi-cylinder which contains no lubrication, making it more susceptible to wear and the need for replacement. The benefits of this type of shear however, are that they work well for non-metallic materials because of their superior ability in the fast production of pressure formed and sheared products. Less shear angle creates a faster production ratio. They also work well with sheet metal, aluminum, and steel. Adjustments for this hydraulic shearing machine can be made in the stroke and pressure which aids in more precision of formation with less distortion of the final product.

Hydraulic guillotine shearing machine

This type of shearing machine has a stronger shearing capacity because of the larger cutting angles which are adjustable. The hydraulic system is programmable to meet the requirements of the project, e.g. stroke pressure, and through the four angle and eight surface right guides. They are precision designed for high accuracy with the capacity for the dual action of an upper stroke and the hydraulic pressure pad on bottom. The accuracy of the hydraulic guillotine shearing machine is higher than that of the swing beam shear, and tends be smoother with less distortion.

Choosing a hydraulic guillotine cutting machine vs swing beam shear

The type of hydraulic cutting machine you choose will be driven by your production needs. There are pros and cons for each type. The guillotine style provides more precision for heavier materials with less distortion, making it a more logical choice for this type of project. The swing beam shear has attributes that make it a better choice when working with lighter materials, however; it can be used accurately with the heavier materials as well.

Preci-Shear Guillotine Shear Machine

The Preci-Shear guillotine shear machine is recommended for metal fabrication projects because of it's precision design that increases smoothness, accuracy and ease of operation. Easy to remove blades make routine maintenance of the unit fast and easy.